The Future of Solar: Self-Cleaning Coatings for Enhanced Efficiency?

Introduction

The global shift towards renewable energy has placed solar power at the forefront of sustainable solutions. However, one of the significant challenges in maintaining solar panel efficiency is keeping them clean.

Dust, dirt, and other contaminants can significantly reduce their performance. Self-cleaning coatings offer a promising solution to this problem. This article explores the future of solar energy with self-cleaning coatings, detailing the technologies, benefits, and potential advancements in the field.

In the relentless pursuit of a sustainable energy future, solar power stands as a beacon of hope. As technology continues to evolve, innovations in the field of solar energy are reshaping the landscape of renewable power generation.

Among these innovations, self-cleaning coatings have emerged as a groundbreaking solution to enhance the efficiency and longevity of solar panels. Join us as we explore the future of solar energy and the transformative potential of self-cleaning coatings in this comprehensive guide.

Understanding Self-Cleaning Coatings

Definition and Purpose

Self-cleaning coatings are specialized surface treatments designed to maintain the cleanliness of solar panels. These coatings help reduce the accumulation of dirt, dust, and other contaminants, thereby enhancing the efficiency and longevity of the panels.

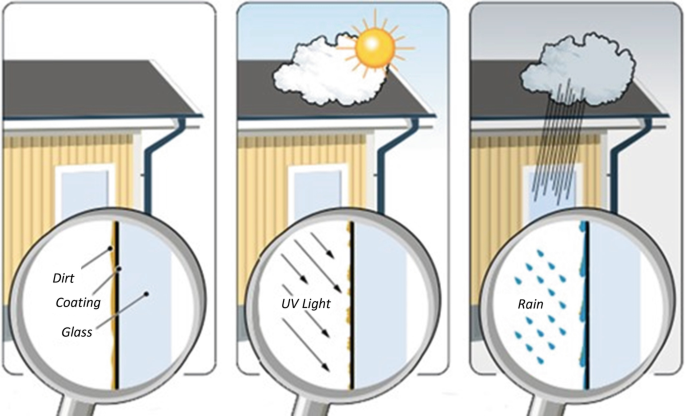

How Self-Cleaning Coatings Work

Self-cleaning coatings work by altering the surface properties of solar panels, making it difficult for contaminants to adhere. They utilize various mechanisms, such as repelling water and breaking down organic matter, to keep the panels clean.

Types of Self-Cleaning Technologies

There are several types of self-cleaning technologies used in solar panels, including hydrophobic, hydrophilic, photocatalytic, and electrostatic coatings. Each type uses a different mechanism to achieve the self-cleaning effect.

Hydrophobic Coatings

Mechanism of Hydrophobic Coatings

Hydrophobic coatings create a water-repellent surface that causes water to bead up and roll off, carrying dirt with it. This is achieved through materials with low surface energy.

Materials Used

Common materials for hydrophobic coatings include silicone-based compounds and fluoropolymers, known for their water-repellent properties.

Advantages and Limitations

Advantages:

- Reduces the frequency of manual cleaning.

- Effective against water-based contaminants.

Limitations:

- Less effective against oily or sticky substances.

- Requires periodic reapplication.

Nanotechnology in Self-Cleaning Coatings

Role of Nanotechnology

Nanotechnology enhances self-cleaning coatings by utilizing materials and structures at the nanoscale. These nanostructures can create superhydrophobic or superhydrophilic surfaces, significantly improving their cleaning capabilities.

Nanomaterials Used

Nanomaterials such as carbon nanotubes, silver nanoparticles, and nano-TiO2 are commonly used to enhance coating properties.

Benefits of Nanoscale Coatings

Benefits:

- Improved durability and longevity.

- Enhanced self-cleaning efficiency.

- Reduced need for reapplication.

Application Techniques for Self-Cleaning Coatings

Surface Preparation

Proper surface preparation is crucial for effective coating application. This involves thorough cleaning to remove contaminants.

Application Methods

Common methods include spray coating, dip coating, and using specialized applicators to ensure an even layer.

Curing and Finishing Processes

Curing can involve air drying, UV curing, or thermal curing, depending on the coating type. Proper curing ensures strong adhesion and effectiveness.

Cost-Benefit Analysis

Initial Costs of Self-Cleaning Coatings

Initial costs vary based on the coating type and quality, as well as the size of the solar panel array. These costs are often justified by long-term benefits.

Long-term Savings

Self-cleaning coatings can significantly reduce maintenance costs and improve the efficiency of solar panels, leading to substantial long-term savings.

Return on Investment (ROI)

The ROI for self-cleaning coatings is generally high, as the enhanced efficiency and reduced maintenance translate to greater energy production and lower operational costs.

Performance Improvements

Efficiency Enhancements

By keeping panels cleaner, self-cleaning coatings help maintain optimal efficiency. Studies have shown that these coatings can improve efficiency by up to 15%.

Longevity of Solar Panels

Self-cleaning coatings protect against environmental damage, extending the lifespan of solar panels and reducing the frequency of replacements.

Maintenance Reduction

The reduced need for manual cleaning and maintenance leads to lower operational costs and less downtime, ensuring that the solar panels are always performing at their best.

Environmental Impact

Eco-Friendly Properties

Many self-cleaning coatings are made from environmentally friendly materials and processes. Additionally, by extending the lifespan of solar panels, these coatings reduce waste.

Contribution to Sustainable Energy

By enhancing the efficiency and durability of solar panels, self-cleaning coatings contribute to the broader goal of sustainable energy production, reducing reliance on fossil fuels.

Reduction in Waste and Replacement

Longer-lasting solar panels mean fewer panels end up in landfills. The reduced need for replacements not only saves money but also minimizes the environmental footprint associated with manufacturing and disposing of solar panels.

Case Studies and Real-World Applications

Successful Implementations

Many solar farms and residential installations have successfully used self-cleaning coatings, resulting in noticeable improvements in performance and durability.

Feedback from Solar Panel Owners

Solar panel owners who have used self-cleaning coatings often report higher satisfaction due to reduced maintenance needs and improved energy output.

Comparative Analysis of Coated vs. Uncoated Panels

Comparative studies consistently show that self-cleaning coated solar panels outperform their uncoated counterparts in terms of efficiency, durability, and maintenance requirements.

Innovations and Future Trends

Advances in Self-Cleaning Coating Technology

Ongoing research and development in self-cleaning coating technology are leading to even more effective and durable products. Innovations such as multifunctional coatings that combine self-cleaning with other beneficial properties are being explored.

Future Applications

Future applications of self-cleaning coatings may extend beyond solar panels to various industrial and consumer products, offering wide-ranging benefits.

Research and Development

Continued investment in research and development is crucial for advancing self-cleaning coating technology. As more is learned about the materials and application processes, the performance and cost-effectiveness of these coatings will likely improve.

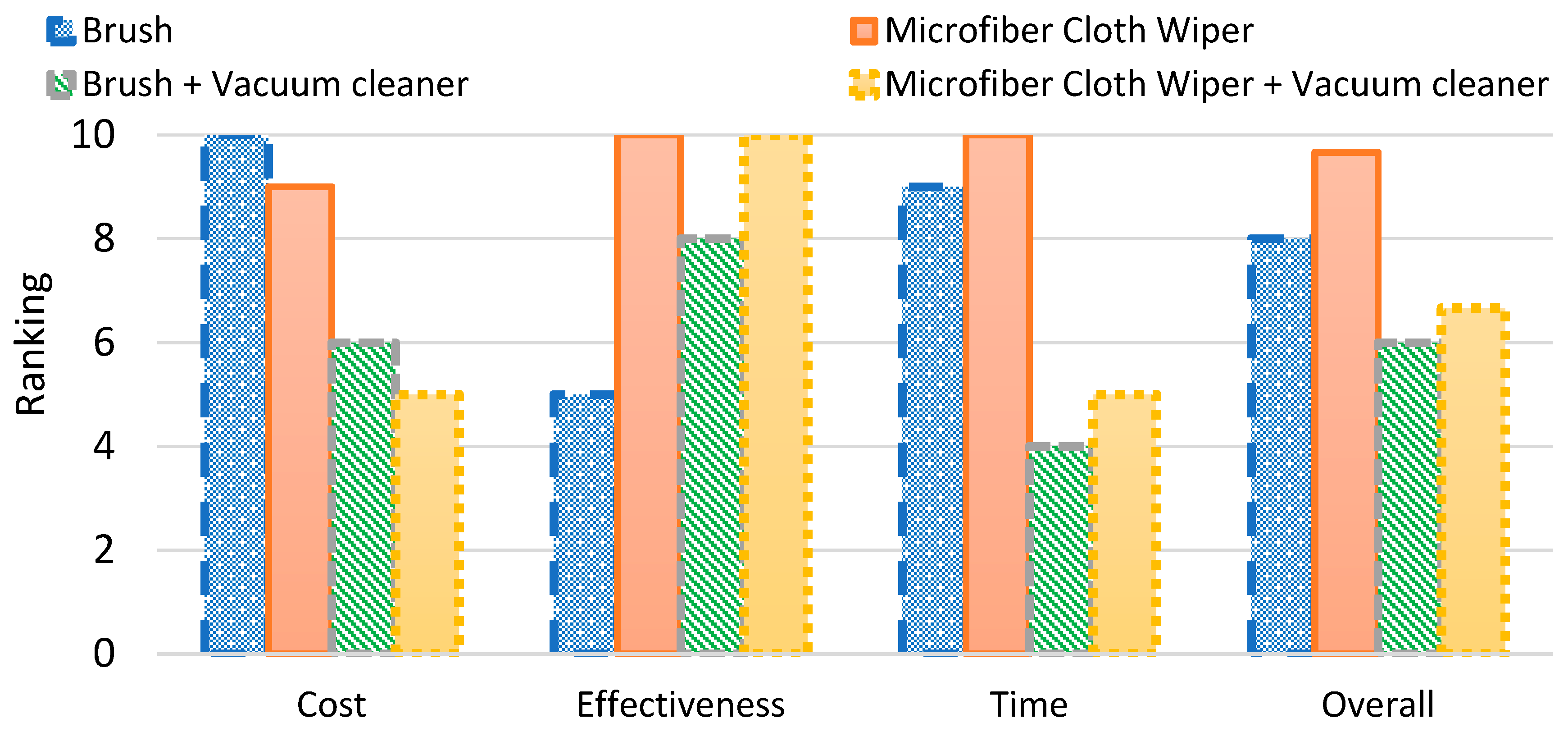

Cost Comparison Table

| Parameter | Self-Cleaning Coated Solar Panels | Non-Coated Solar Panels |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance Frequency | Lower | Higher |

| Efficiency Improvement | 10-15% Increase | No Improvement |

| Lifespan | Extended | Standard |

| Environmental Impact | Lower Carbon Footprint | Higher Carbon Footprint |

| Long-term Savings | Higher | Lower |

Environmental Impact of Solar Panels

The Imperative of Efficiency in Solar Energy

- The growing demand for clean and sustainable energy solutions

- Importance of maximizing solar panel efficiency to meet energy needs

- Challenges posed by dust, dirt, and environmental factors on solar panel performance.

Introducing Self-Cleaning Coatings

- Evolution of coatings technology in the solar industry

- Advantages of self-cleaning coatings over traditional methods

- How self-cleaning coatings work to maintain solar panel efficiency

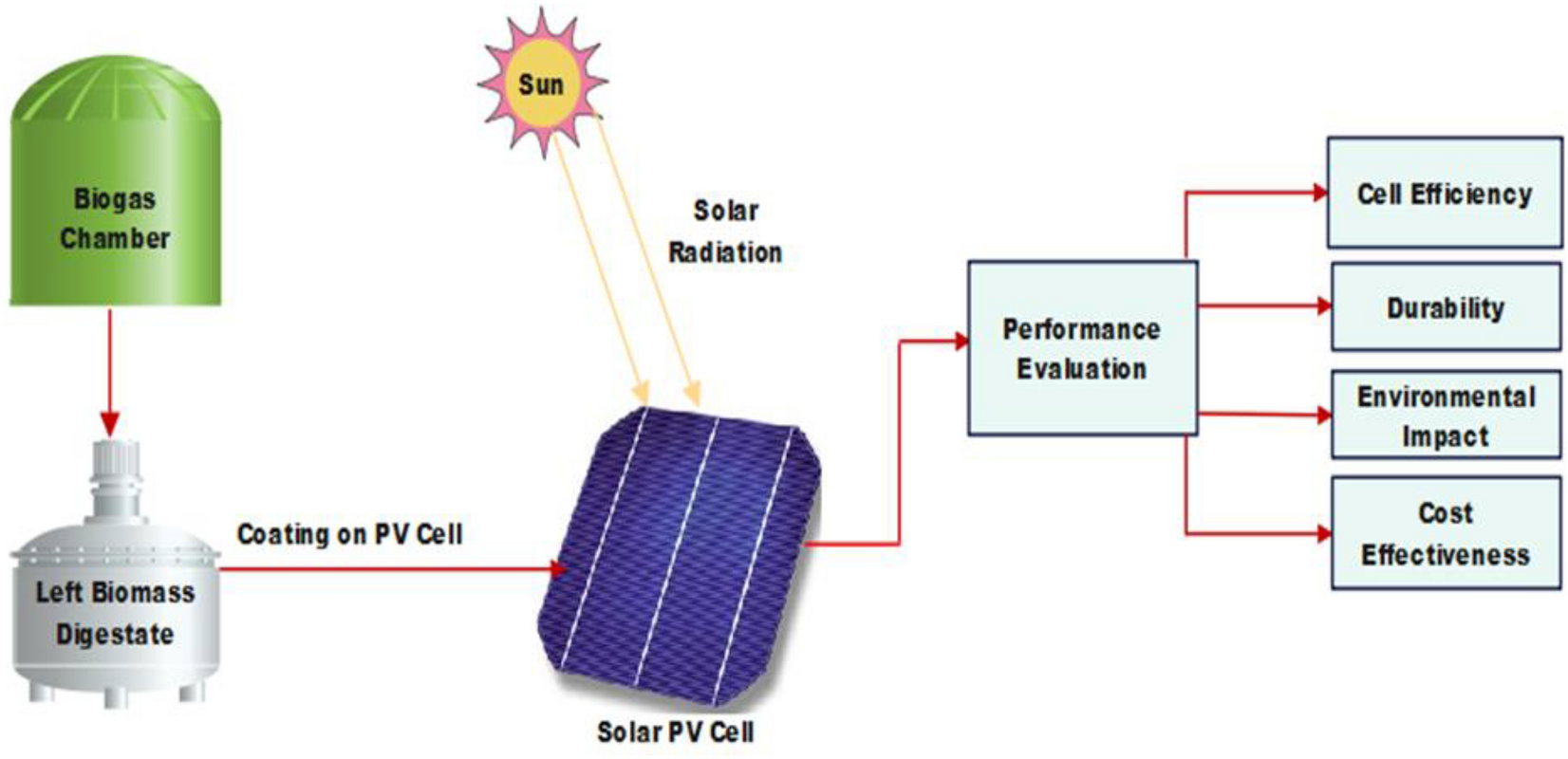

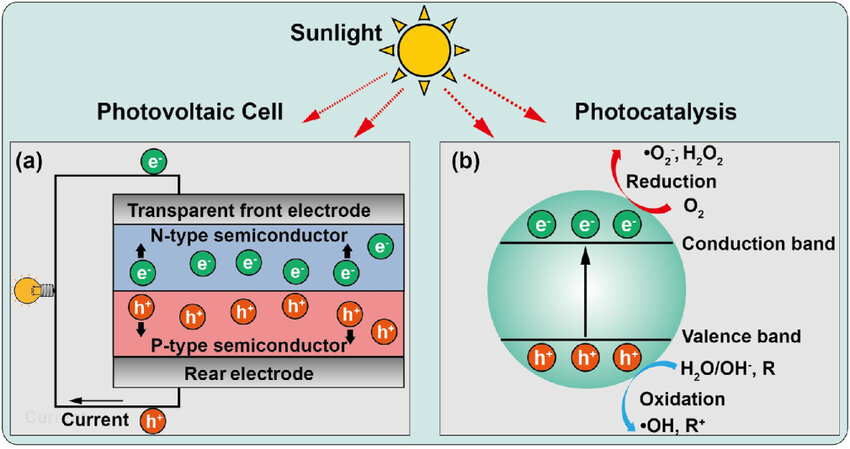

The Science Behind Self-Cleaning Technology

- Photocatalysis: A key mechanism driving self-cleaning action

- Role of nanoparticles in breaking down organic contaminants

- Hydrophobicity and its contribution to dust repellence

Benefits of Self-Cleaning Coatings for Solar Panels

- Increased energy production through improved light absorption

- Reduced maintenance costs and labor requirements

- Extended lifespan of solar panels

- Environmental benefits: Water conservation and reduced chemical usage

Overcoming Challenges and Limitations

- Durability and stability of self-cleaning coatings under harsh environmental conditions

- Compatibility with different types of solar panel materials

- Cost considerations and scalability of production

Real-World Applications and Success Stories

- Case studies highlighting the effectiveness of self-cleaning coatings in various settings

- Commercial and residential applications of self-cleaning technology

- Market trends and adoption rates of self-cleaning coatings in the solar industry

Environmental Considerations and Regulatory Frameworks

- Assessment of environmental impact associated with self-cleaning coatings

- Regulatory standards governing the use and disposal of nanomaterials

- Sustainable manufacturing practices and waste management strategies

Looking Ahead: The Future of Solar Energy

- Technological advancements in self-cleaning coatings and solar panel design

- Integration of self-cleaning technology with emerging solar technologies

- Role of research and innovation in driving the evolution of solar energy

Conclusion

Self-cleaning solar panel coatings represent a significant advancement in renewable energy technology. By utilizing various technologies such as hydrophobic, hydrophilic, photocatalytic, and electrostatic coatings, these solutions enhance the efficiency, durability, and sustainability of solar panels.

As technology continues to evolve, the benefits of self-cleaning coatings will become even more pronounced, making them an essential component of modern solar energy systems.

As we stand at the brink of a new era in renewable energy, self-cleaning coatings represent a pivotal advancement in the quest for efficient and sustainable solar power.

By harnessing the power of innovation and science, we have the potential to unlock unprecedented opportunities for clean energy generation. The future of solar energy is bright, and self-cleaning coatings are poised to play a central role in shaping that future.

Join us as we embark on this journey towards a cleaner, greener tomorrow powered by the sun.

Frequently Asked Questions (FAQs)

What Are Self-Cleaning Solar Panel Coatings Made Of?

Self-cleaning coatings are typically made of materials such as titanium dioxide, silicon dioxide, and various nanomaterials that provide hydrophobic, hydrophilic, or photocatalytic properties.

How Long Do Self-Cleaning Coatings Last?

The longevity of self-cleaning coatings can vary, but high-quality coatings can last for several years, often extending the lifespan of the solar panels themselves.

Are Self-Cleaning Coatings Environmentally Friendly?

Yes, many self-cleaning coatings are made from environmentally friendly materials and processes. They contribute to sustainable energy production by improving the efficiency and lifespan of solar panels.

How Do Self-Cleaning Coatings Affect Solar Panel Efficiency?

Self-cleaning coatings improve solar panel efficiency by keeping the surface clean, which allows more sunlight to be absorbed and converted into electricity.

Can Self-Cleaning Coatings Be Applied to Existing Panels?

Yes, self-cleaning coatings can be retrofitted to existing solar panels. Proper surface preparation and application techniques are crucial to ensure effective bonding and performance.