What Technology is Used in Self-Cleaning Solar Panel Coatings?

Introduction

Solar panels are pivotal in the shift toward renewable energy, yet their efficiency can be significantly reduced by dirt, dust, and other contaminants. Self-cleaning solar panel coatings offer a solution to maintain optimal performance with minimal maintenance.

This article delves into the various technologies behind these coatings, exploring their mechanisms, benefits, and real-world applications.

Self-cleaning coatings have emerged as a cost-effective solution for maintaining the efficiency of solar panels while minimizing maintenance efforts. Let’s explore how these innovative coatings can significantly reduce maintenance costs for solar panel owners.

Understanding Self-Cleaning Solar Panel Coatings

Definition and Purpose

Self-cleaning solar panel coatings are specialized surface treatments that help maintain the cleanliness of solar panels by repelling or breaking down contaminants. These coatings ensure that the panels remain efficient and require less frequent manual cleaning.

How Self-Cleaning Coatings Work

These coatings work by altering the surface properties of solar panels. They either repel water and dirt or break down organic matter using light energy, ensuring that the panels stay clean and efficient.

Types of Self-Cleaning Technologies

The main types of self-cleaning technologies include hydrophobic, hydrophilic, photocatalytic, and electrostatic coatings. Each uses different mechanisms to achieve the self-cleaning effect.

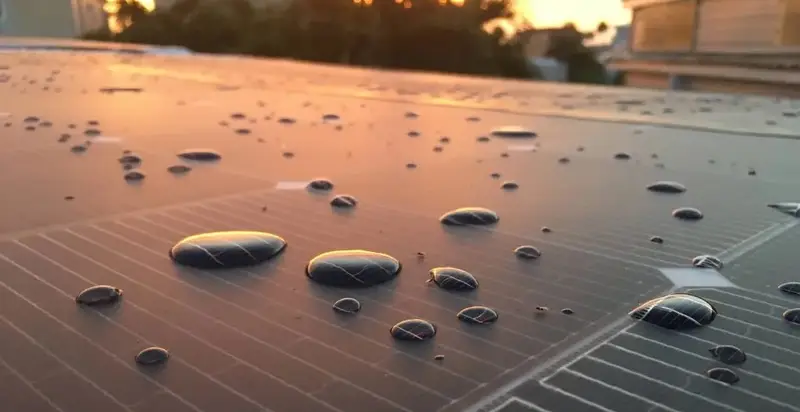

Hydrophobic Coatings

– How Hydrophobic Coatings Work

Hydrophobic coatings create a water-repellent surface that causes water to bead up and roll off, carrying dirt with it. This is achieved by applying materials with low surface energy.

– Materials Used in Hydrophobic Coatings

Silicone-based compounds and fluoropolymers are commonly used due to their effective water-repellent properties.

– Advantages and Limitations

Advantages:

- Reduces the frequency of manual cleaning.

- Effective against water-based contaminants.

Limitations:

- May be less effective against oily or sticky substances.

- Requires periodic reapplication.

Hydrophilic Coatings

– How Hydrophilic Coatings Work

Hydrophilic coatings attract water, spreading it into a thin film that washes away dirt. They often use materials like titanium dioxide (TiO2), which become highly hydrophilic under UV light.

– Materials Used in Hydrophilic Coatings

Titanium dioxide is the most commonly used material due to its photocatalytic and hydrophilic properties.

– Advantages and Limitations

Advantages:

- Effective in various weather conditions.

- Suitable for areas with frequent rain.

Limitations:

- Requires UV light to maintain hydrophilic properties.

- Less effective in dry environments.

Photocatalytic Coatings

– Mechanism of Photocatalytic Action

Photocatalytic coatings use materials that react with sunlight to break down organic contaminants. Titanium dioxide is a key material, reacting with UV light to create reactive oxygen species that decompose organic matter.

– Common Photocatalytic Materials

Titanium dioxide and zinc oxide are commonly used due to their strong photocatalytic properties.

– Advantages and Limitations

Advantages:

- Highly effective at breaking down organic contaminants.

- Reduces the need for manual cleaning.

Limitations:

- Requires UV light for activation.

- Less effective against inorganic contaminants.

Electrostatic Coatings

– How Electrostatic Coatings Work

Electrostatic coatings create a surface charge that repels dust and other particles. Conductive materials maintain an electrostatic charge, reducing particle accumulation.

– Materials and Mechanisms

Conductive polymers and certain metal oxides are used to create an electrostatic effect.

– Advantages and Limitations

Advantages:

- Effective in dry and dusty environments.

- Reduces accumulation of both organic and inorganic particles.

Limitations:

- May require an external power source.

- Less effective in humid conditions.

Nanotechnology in Self-Cleaning Coatings

Role of Nanotechnology

Nanotechnology enhances self-cleaning coatings by utilizing materials and structures at the nanoscale, creating superhydrophobic or superhydrophilic surfaces.

Nanomaterials Used

Nanomaterials such as carbon nanotubes, silver nanoparticles, and nano-TiO2 are used to enhance coating properties.

Benefits of Nanoscale Coatings

Benefits:

- Improved durability and longevity.

- Enhanced self-cleaning efficiency.

- Reduced need for reapplication.

Application Techniques for Self-Cleaning Coatings

Surface Preparation

Proper surface preparation is crucial for effective coating application. This involves thorough cleaning to remove contaminants.

Application Methods

Common methods include spray coating, dip coating, and using specialized applicators to ensure an even layer.

Curing and Finishing Processes

Curing can involve air drying, UV curing, or thermal curing, depending on the coating type. Proper curing ensures strong adhesion and effectiveness.

Cost-Benefit Analysis

Initial Costs of Self-Cleaning Coatings

Initial costs vary based on the coating type and quality, as well as the size of the solar array. These costs are often offset by long-term benefits.

Long-term Savings

Self-cleaning coatings reduce maintenance costs and improve solar panel efficiency, leading to substantial long-term savings.

Return on Investment (ROI)

The ROI for self-cleaning coatings is generally high due to enhanced efficiency and reduced maintenance costs, resulting in greater energy production and lower operational expenses.

Performance Improvements

Efficiency Enhancements

By keeping panels cleaner, self-cleaning coatings help maintain optimal efficiency. These coatings can improve efficiency by up to 15%.

Longevity of Solar Panels

Self-cleaning coatings protect against environmental damage, extending the lifespan of solar panels.

Maintenance Reduction

Reduced need for manual cleaning and maintenance lowers operational costs and ensures consistent panel performance.

Environmental Impact

Eco-Friendly Properties

Many self-cleaning coatings are made from environmentally friendly materials and processes. They also reduce the environmental impact by extending panel lifespan.

Contribution to Sustainable Energy

By improving efficiency and durability, self-cleaning coatings contribute to sustainable energy production, reducing reliance on fossil fuels.

Reduction in Waste and Replacement

Longer-lasting panels mean fewer replacements, reducing waste and the environmental footprint of manufacturing new panels.

Case Studies and Real-World Applications

Successful Implementations

Many solar farms and residential installations have successfully used self-cleaning coatings, resulting in improved performance and durability.

Feedback from Solar Panel Owners

Users report higher satisfaction due to reduced maintenance needs and improved energy output.

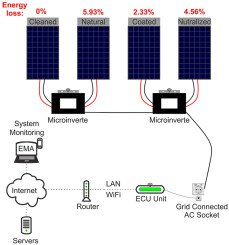

Analysis of Coated and Uncoated Panels

Studies consistently show that self-cleaning coated panels outperform uncoated panels in efficiency, durability, and maintenance requirements.

Innovations and Future Trends

Advances in Self-Cleaning Coating Technology

Research is leading to more effective and durable products, including multifunctional coatings that combine self-cleaning with other beneficial properties.

Future Applications

Future applications may extend beyond solar panels to various industrial and consumer products.

Research and Development

Continued investment in research and development is crucial for advancing self-cleaning coating technology.

Cost Comparison Table

| Parameter | Self-Cleaning Coated Solar Panels | Non-Coated Solar Panels |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance Frequency | Lower | Higher |

| Efficiency Improvement | 10-15% Increase | No Improvement |

| Lifespan | Extended | Standard |

| Environmental Impact | Lower Carbon Footprint | Higher Carbon Footprint |

| Long-term Savings | Higher | Lower |

Self-Cleaning’ Solar Panel Coating

1. Hydrophobic and Superhydrophobic Properties:

2. Surface Textures and Nanostructures:

3. Lotus Effect:

4. Photocatalytic and Anti-Adhesive Materials:

5. Environmental Interaction:

Frequently Asked Questions (FAQs)

What Are Self-Cleaning Solar Panel Coatings Made Of?

Self-cleaning coatings are typically made of materials like titanium dioxide, silicon dioxide, and various nanomaterials providing hydrophobic, hydrophilic, or photocatalytic properties.

How Long Do Self-Cleaning Coatings Last?

High-quality self-cleaning coatings can last for several years, often extending the lifespan of the solar panels themselves.

Are Self-Cleaning Coatings Environmentally Friendly?

Yes, many self-cleaning coatings are made from environmentally friendly materials and processes. They contribute to sustainable energy by improving the efficiency and lifespan of solar panels.

How Do Self-Cleaning Coatings Affect Solar Panel Efficiency?

They improve solar panel efficiency by keeping the surface clean, allowing more sunlight to be absorbed and converted into electricity.

Can Self-Cleaning Coatings Be Applied to Existing Panels?

Yes, self-cleaning coatings can be retrofitted to existing panels. Proper surface preparation and application techniques are crucial to ensure effective bonding and performance.

Conclusion

Self-cleaning solar panel coatings represent a significant advancement in renewable energy technology. By utilizing various technologies such as hydrophobic, hydrophilic, photocatalytic, and electrostatic coatings, these solutions enhance the efficiency, durability, and sustainability of solar panels.

As technology continues to evolve, the benefits of self-cleaning coatings will become even more pronounced, making them an essential component of modern solar energy systems.

Self-cleaning solar panel coatings leverage advanced technology, including hydrophobic and superhydrophobic properties, surface textures, nanostructures, photocatalytic materials, and anti-adhesive coatings, to repel dirt and maintain optimal performance.

Inspired by nature’s own mechanisms, these coatings ensure that solar panels remain clean and efficient, maximizing energy production and sustainability.

As the demand for renewable energy continues to grow, self-cleaning coatings play a crucial role in driving the efficiency and affordability of solar power, paving the way for a cleaner and more sustainable future.